Lean Manufacturing Value Stream Mapping

Vsm optimisation with use of value stream mapping 24 04 2015. At its root value stream mapping is a tool used in lean manufacturing to reduce waste and therefore increase efficiency and value production.

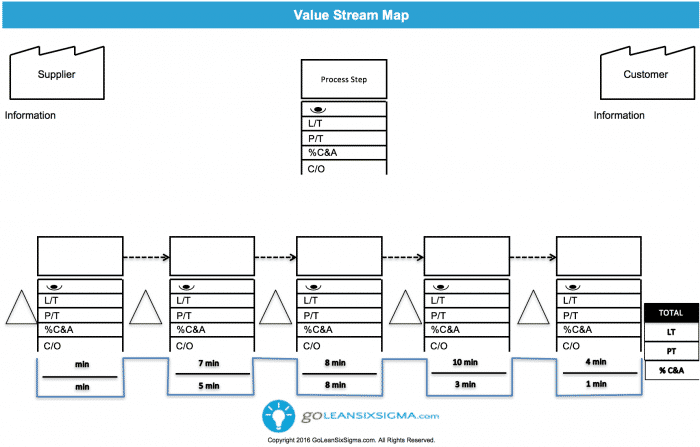

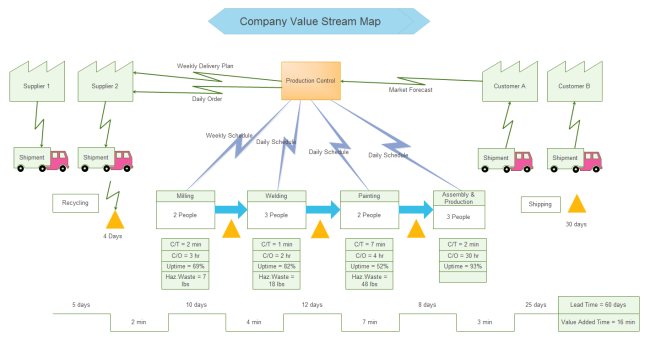

Value Stream Map Template Example

Value Stream Map Template Example

Lean manufacturing pdf lean manufacturing tools 24 0 0.

Lean manufacturing value stream mapping

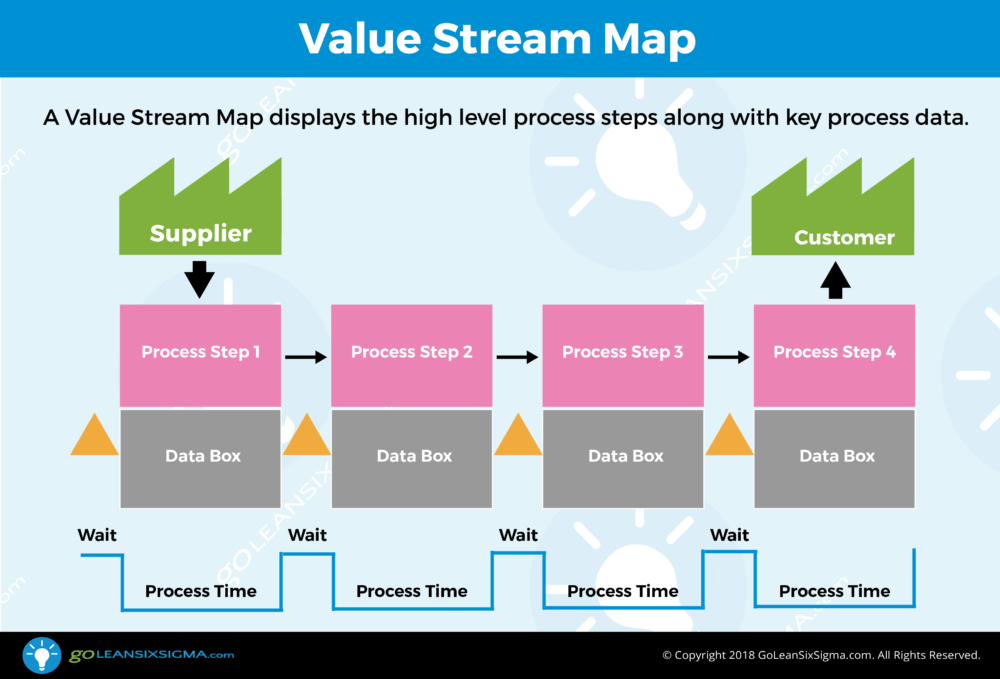

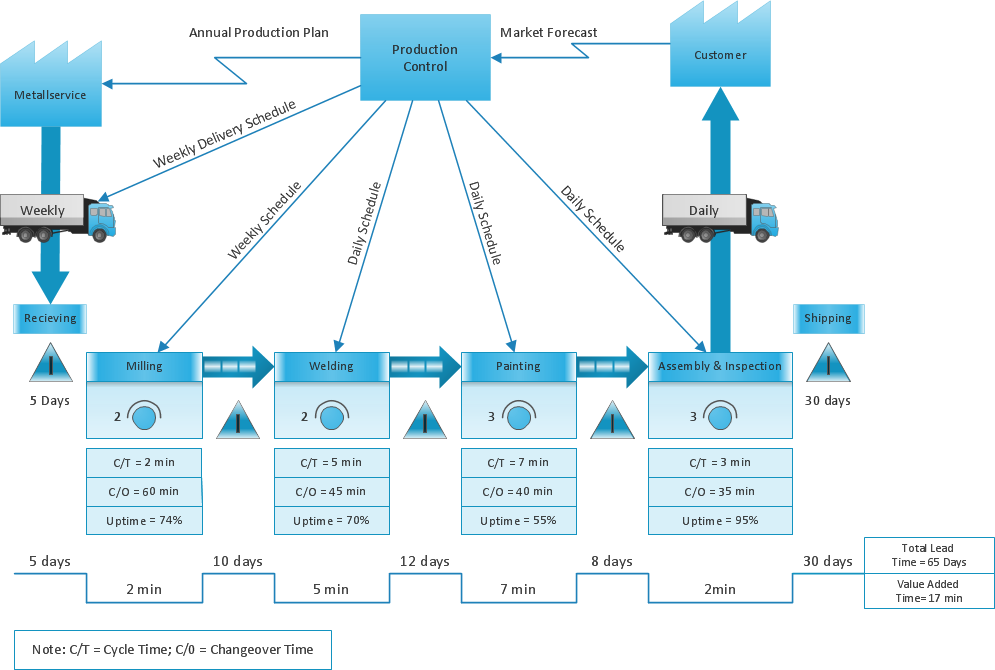

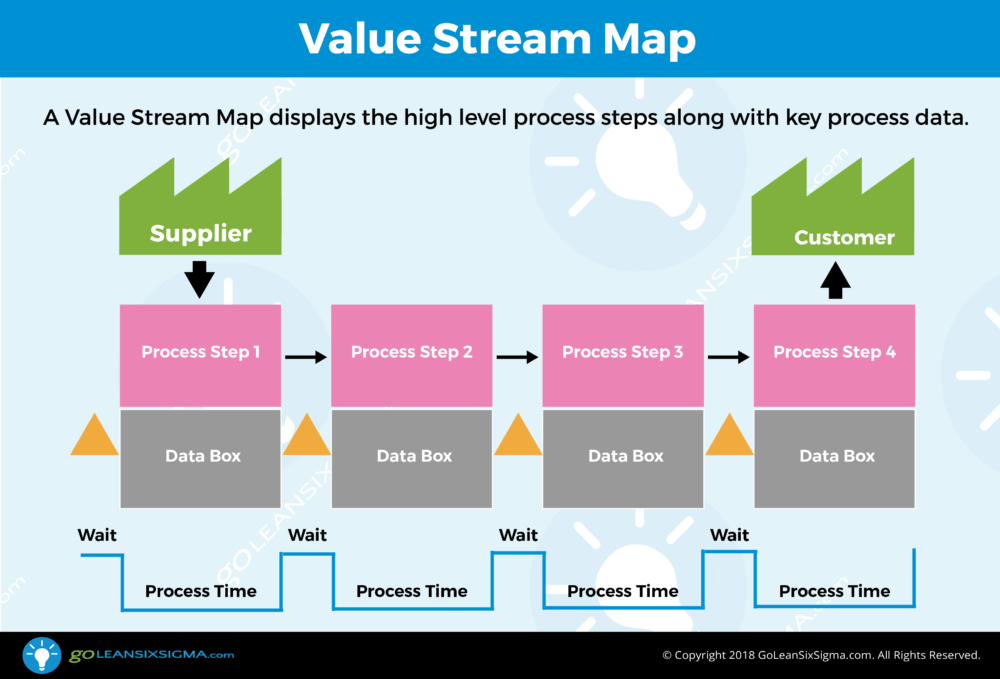

. It can be applied to nearly any value chain. The value stream map is a paper and pencil representation of every process in the material and information flow of a product or product family along with key data. Value stream mapping is a lean management method for analyzing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer. Value stream map tool that provides visualization and understanding of the flow of material and information as a product or service makes its way through the value stream and can be used to present both current state as well as future state vision.It differs significantly from tools such as process mapping or layout diagrams because it includes information flow as well as material flow. Value stream mapping is a technique developed from lean manufacturing that organizations use to create a visual guide of all the components necessary to deliver a product or service with the goal of analyzing and optimizing the entire process. In the times where the financial crisis affects an. One of the most important achievements in terms of maintenance of low prices of our products is gradual shortening of the production cycle.

They are accomplishing it for impact. This mapping tool uses the techniques of lean manufacturing to analyze and evaluate certain work processes in a manufacturing operation. Knowledge lean manufacturing. Value stream mapping using simulation towards lean manufacturing at manufacturing company.

Value stream mapping a lean manufacturing tool which originated from the tps is known as material and information flow mapping. What is lean value stream mapping vsm. Lean manufacturing and value stream mapping software by josefadominquez july 27 2020 once certification is obtained it is really important to together with mind motive for corporations choose six sigma. Przeczytanie artykułu zajmie ci 4 minuty.

Here you are. At toyota it is known as material and information flow mapping. And that s important because as you may remember lean manufacturing is all about reducing waste and increasing value. Value stream mapping vsm is a lean manufacturing tool that seeks to map your process from supplier to customer highlighting the flows of product and information and identifying delays and non value adding processes.

The longer the product dwells in the production process and the longer it is transferred the higher is its final cost 1926 henry ford.

What Is Value Stream Mapping Value Stream Mapping Software

What Is Value Stream Mapping Value Stream Mapping Software

Value Stream Map Lean Manufacturing And Six Sigma Definitions

Vsm Value Stream Mapping

Vsm Value Stream Mapping

Value Stream Mapping Lean Manufacturing Principles Part 4

Value Stream Mapping Lean Manufacturing Principles Part 4

Value Stream Mapping In Six Sigma

Value Stream Mapping In Six Sigma

Value Stream Mapping Purdue Lean Six Sigma Online

Value Stream Mapping Purdue Lean Six Sigma Online

Value Stream Map Template Example

Value Stream Map Template Example

What Is Value Stream Mapping Vsm Benefits Process And Value

What Is Value Stream Mapping Vsm Benefits Process And Value

Value Stream Map Examples Value Stream Mapping Lean

Value Stream Map Examples Value Stream Mapping Lean

Value Stream Mapping Wikipedia

Value Stream Mapping Wikipedia

Value Stream Mapping Example 3 Value Stream Map Template

Value Stream Mapping Example 3 Value Stream Map Template

Post a Comment for "Lean Manufacturing Value Stream Mapping"