Value Stream Mapping Analysis

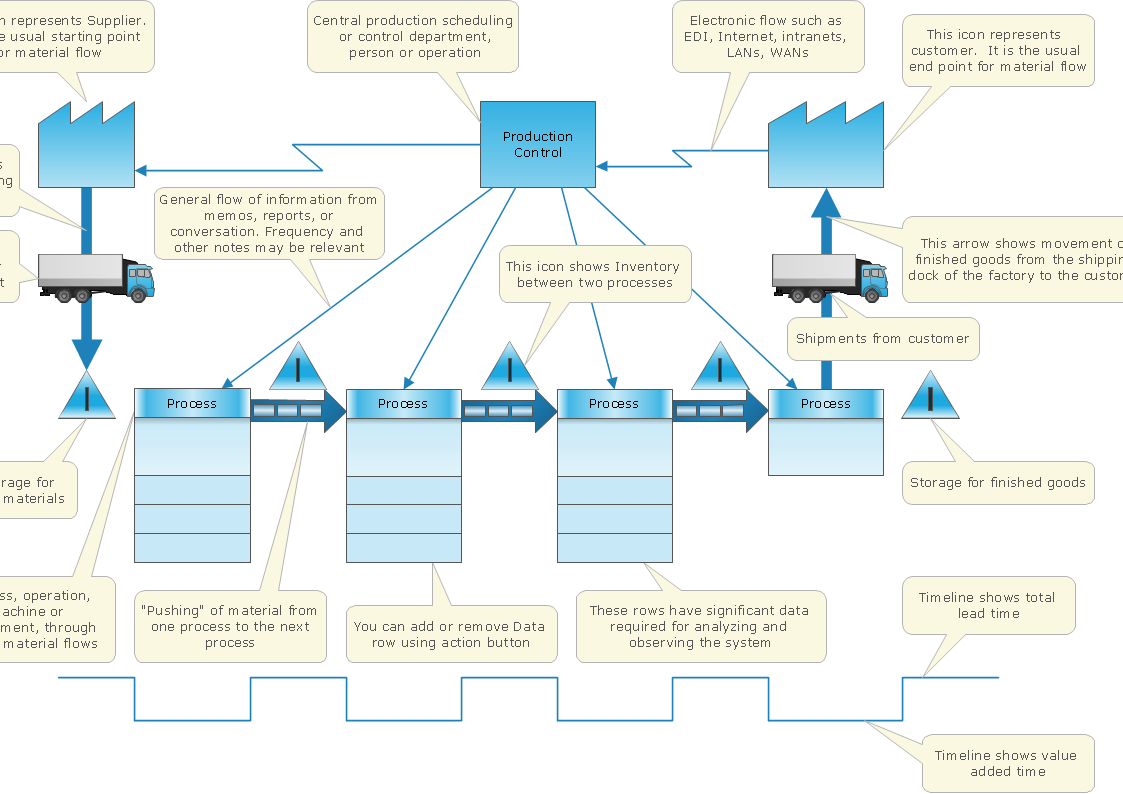

Also known as material and information flow mapping it uses a system of standard symbols to depict various work streams and information flows. It enables to identify and eliminate waste in order to streamline work processes cut lead times reduce costs and increase quality thus enabling on time delivery and first time right product or service.

Value Stream Mapping Strategos

Value stream mapping is a lean management tool that helps visualize the steps needed to take from product creation to delivering it to the end customer.

Value stream mapping analysis

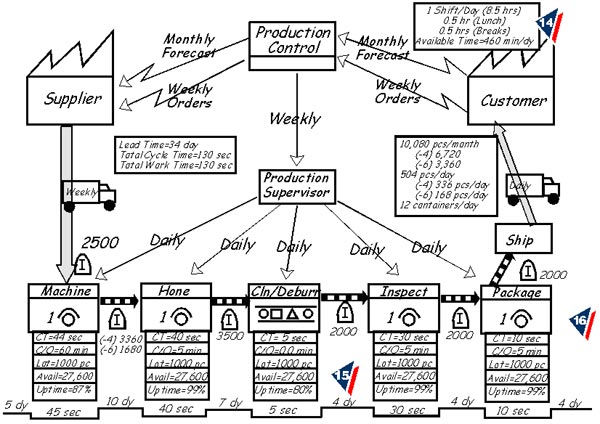

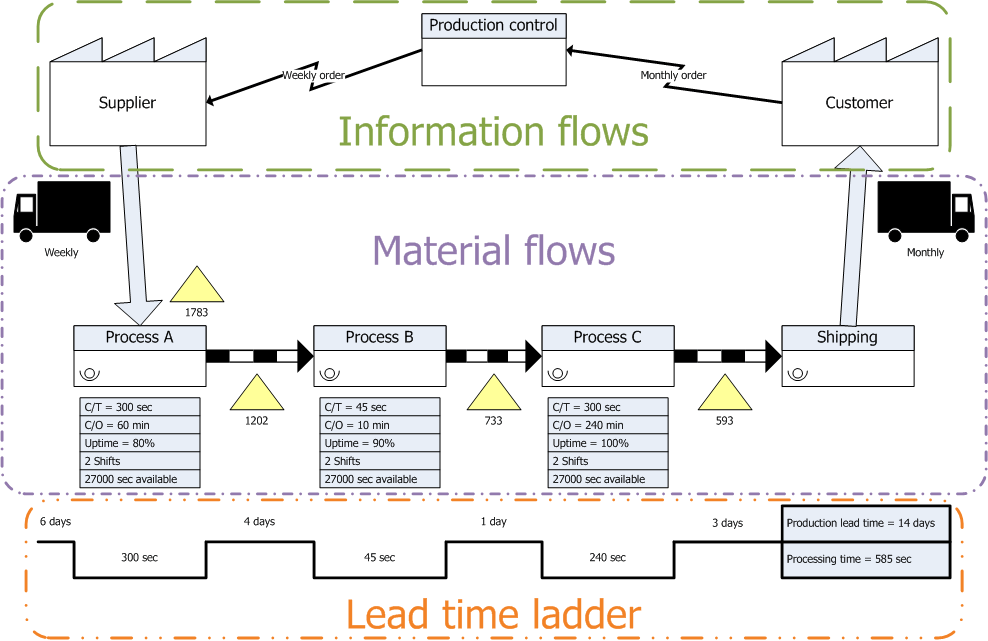

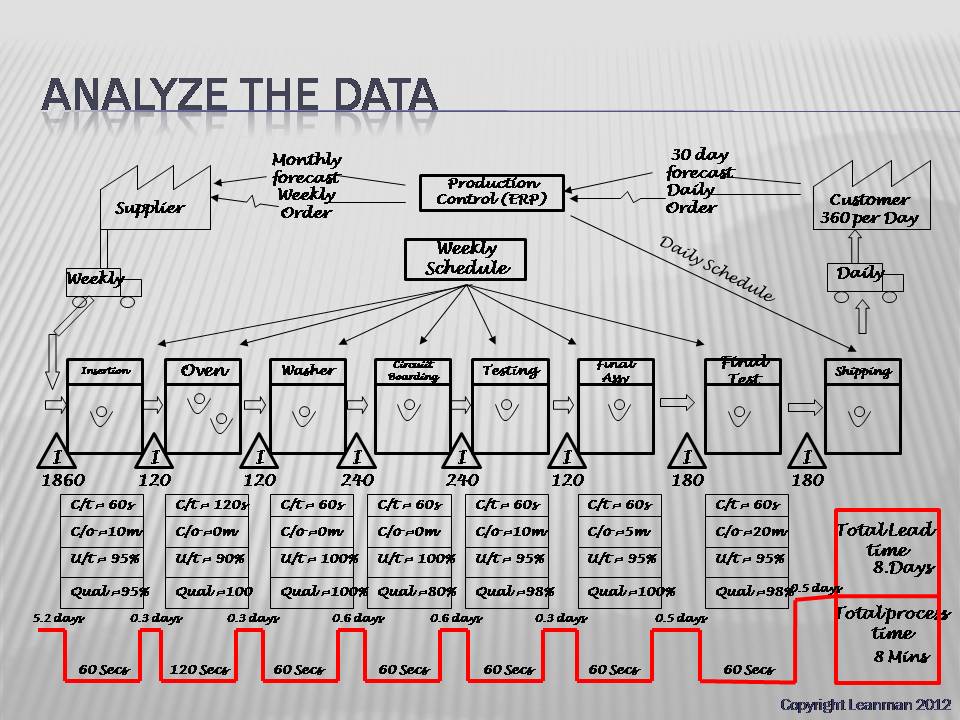

. Value stream mapping is a flowchart method to illustrate analyze and improve the steps required to deliver a product or service. The model which contains both values adding steps and non value adding steps from the customers standpoint is similar to the flowchart structure. Value stream mapping sometimes called vsm is a lean manufacturing technique to analyze design and manage the flow of materials and information required to bring a product to a customer. Value stream mapping vsm gives us the opportunity to see the hidden risks and potential that we miss in our day to day processes and take clear and confident steps towards better.Improvements value stream mapping analysis strengthens the gains by providing vision and plans that connect all improvement activities value stream mapping analysis is a tool that allows you to see waste and plan to eliminate it. Value stream mapping vsm is a lean manufacturing technique used to analyze and design the flow of material and or information. A key part of lean methodology vsm reviews the flow of process steps and information from origin to delivery to the customer. As with other business process mapping methods it helps with introspection understanding your business better as well as analysis and process improvement.

I ve been facilitating value stream definition and improvement as a technical leader for over 5 years the past 2 as a consultant to companies of all sizes. Value stream mapping also known as material and information flow mapping is a lean management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. Value stream analysis lean process mapping value stream mapping vsm is defined as a lean tool that employs a flowchart documenting every step in the process. Value stream mapping vsm is a technique used by firms to define analyze and optimize the information materials flow required to the whole production process.

Many lean practitioners see vsm as a fundamental tool to identify waste reduce process cycle times and implement process improvement. This mapping event can be divided into 4 stages that are described in detail below. Value stream map analysis and best practices a value stream map outlines the sequence from the input of raw materials to the delivery of the finished goods or services to the customer.

10 Easy Steps To Complete A Value Stream Map Vsm

10 Easy Steps To Complete A Value Stream Map Vsm

Value Stream Mapping And Analysis Value Stream Mapping Software

Value Stream Mapping And Analysis Value Stream Mapping Software

Value Stream Mapping Tutorial Value Stream Mapping Explained

Value Stream Mapping Tutorial Value Stream Mapping Explained

How To Finish Your Value Stream Map Analysis Bizmanualz

How To Finish Your Value Stream Map Analysis Bizmanualz

Value Stream Mapping Definition Steps And Examples Tallyfy

Value Stream Mapping Definition Steps And Examples Tallyfy

Creating A Value Stream Map

Creating A Value Stream Map

What Is Value Stream Mapping Vsm Benefits Process And Value

What Is Value Stream Mapping Vsm Benefits Process And Value

Value Stream Analysis Value Stream Mapping Software

Value Stream Analysis Value Stream Mapping Software

Value Stream Mapping Templates To Quickly Analyze Your Workflows

Value Stream Mapping Templates To Quickly Analyze Your Workflows

What Is Value Stream Mapping Vsm Benefits Process And Value

What Is Value Stream Mapping Vsm Benefits Process And Value

Post a Comment for "Value Stream Mapping Analysis"